Spray Drying

Spray drying is a process that turns a liquid or slurry into a dry powder by rapidly drying it with a hot gas.

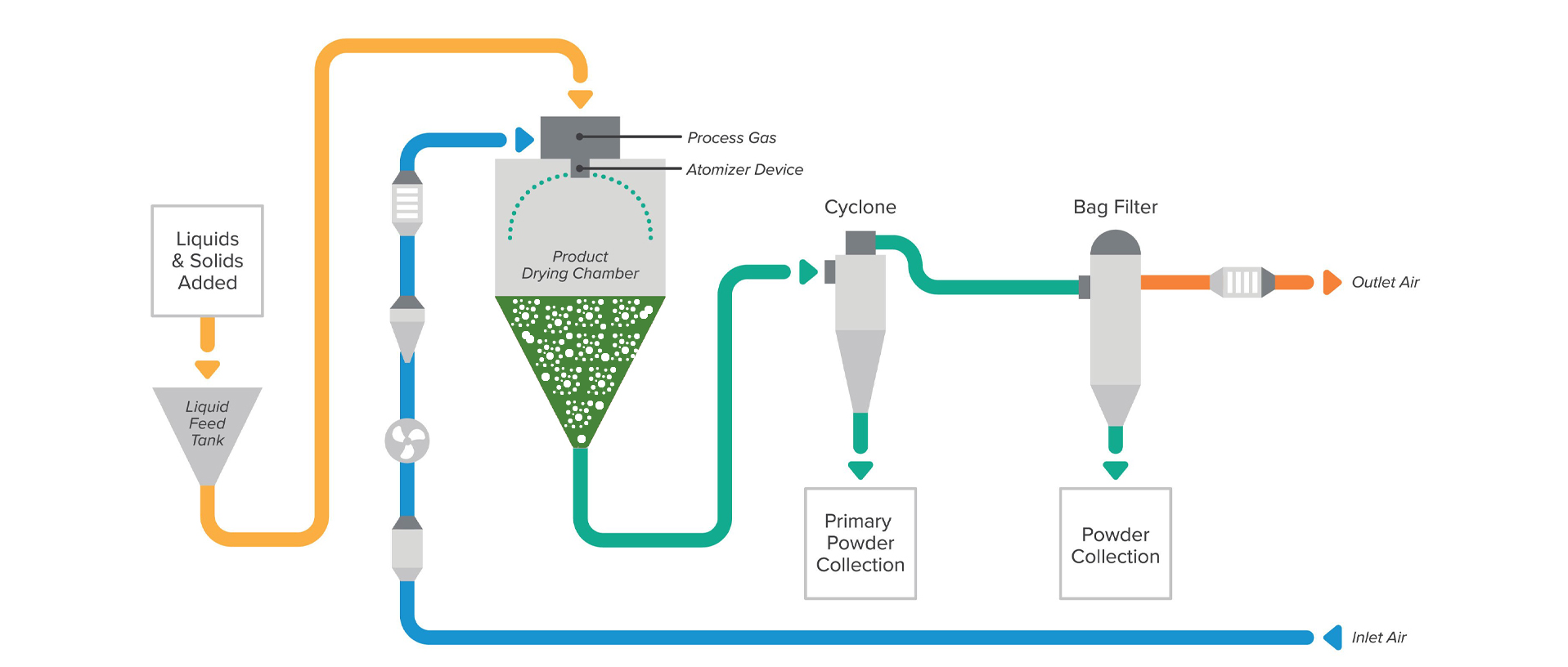

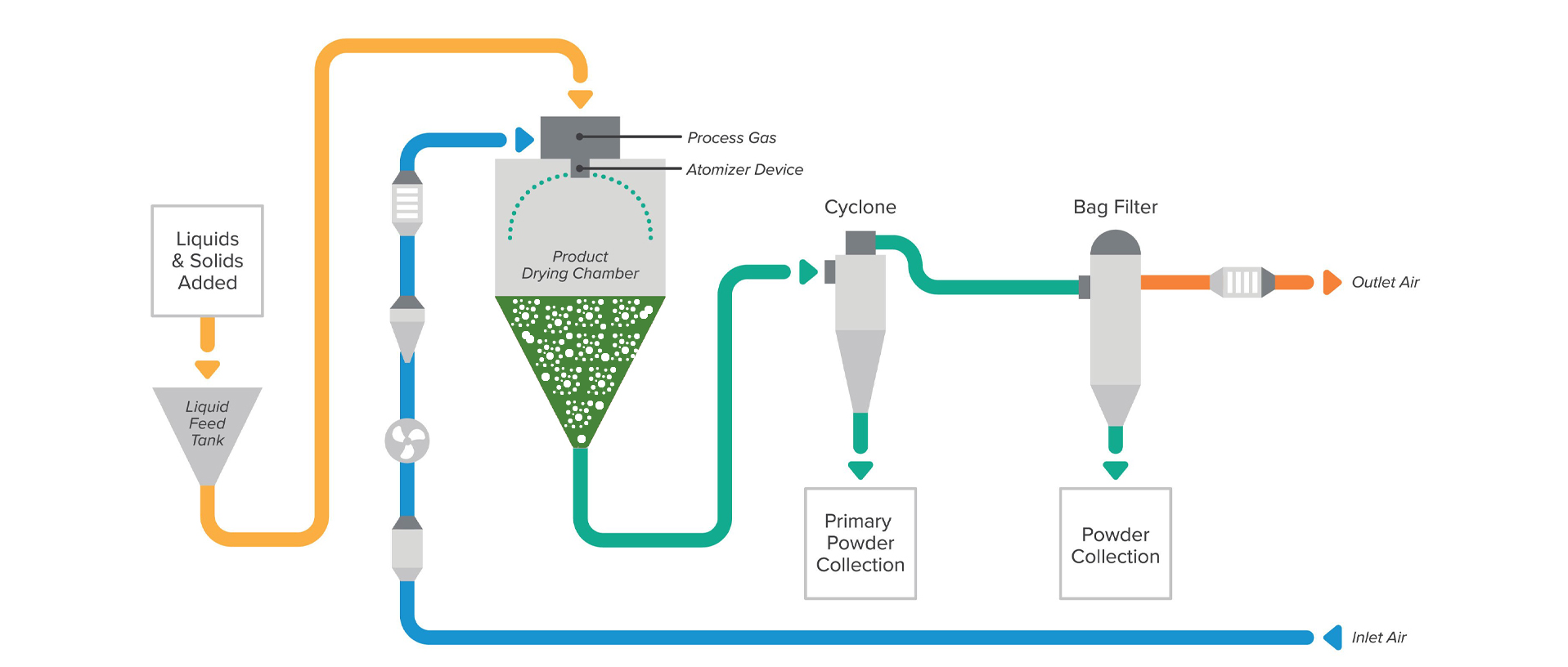

The spray drying process involves the following steps

- Atomization: The liquid is dispersed into a controlled spray of droplets using a spray nozzle or atomizer.

- Drying: The spray is dried in the hot gas stream.

- Formation: The droplets form dry particles.

- Collection: The dry product is separated and collected from the drying gas.

Process of Spray Drying

Some advantages of spray drying include:

- Low operating costs: Spray drying is energy-efficient and has low operating costs.

- Fast processing: Spray drying is a fast process.

- High encapsulation efficiency: Spray drying has a high encapsulation efficiency.

- Encapsulated product stability: The encapsulated product is stable.

- Control over particle size: The size, shape, and morphology of the particles can be controlled.