Bromine is a naturally occurring halogen element with the atomic symbol ‘Br’. It is one of only two elements on the periodic table known to be liquids (the other being mercury) and it is the only non-metal element to exist in liquid form at room temperature and pressure.

Bromine is a commercially important chemical which can be recovered from Sea – water or form salt water bitterns; which is the concentrated sea water left over after the extraction of salt. Theoretically for every Kilogram of salt produced there is one Kilogram of bittern left behind. The concentration of Bromine is proportional to the concentration of sea – Water. Bittern at 29° Be contains approximately 2.85 g.p.l of BROMINE. Bromine content is proportional to the concentration of it is worthwhile to note that sodium chloride precipitates between 24° Be and 28 ° Be.

On the other way, Bromine is produced from lower density sea brine from 10 to 15 deg Be which contains 500 ppm Bromine content. As the concentration of Bromine is less, the quantum of brine required is very high . The consistent availability of brine in terms of quality and quantity throughout the year from bore wells makes the project viable. In few countries the brine available at these concentration and they produce Bromine in large quantity.

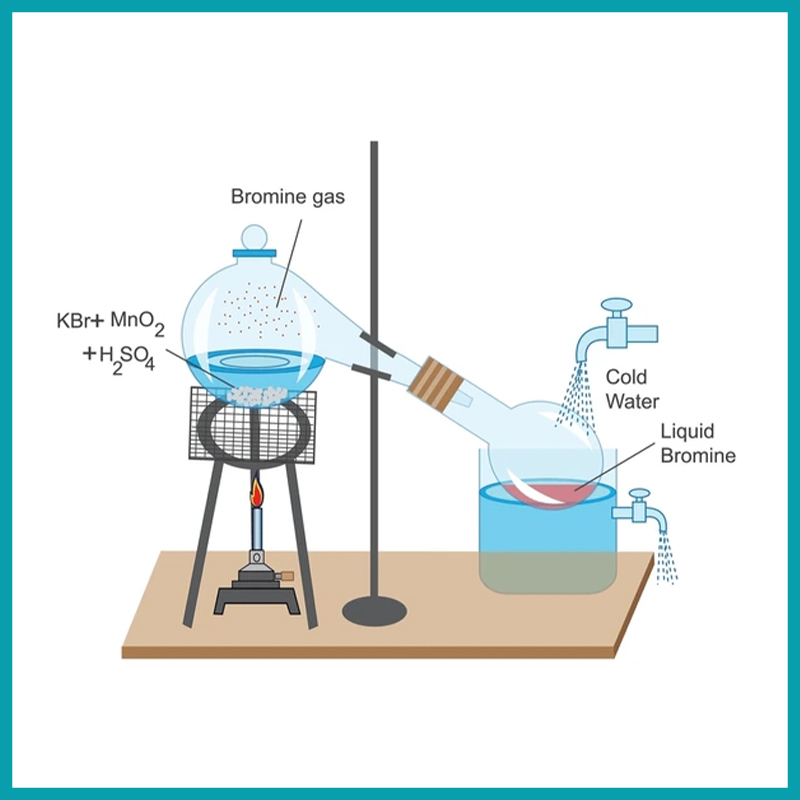

Bromine can be produced by COLD and HOT process, as detailed below:

In the cold process there are two stages, the acidified brine is chlorinated then stripped in a column using air and then the librated Bromine is mixed with Sulpphur dioxide gas in presence of water , forms Hydrobromic Acid and Suphuric Acid Mixture. Thus obtained Bromide mixture is Chlorinated again in a tower and bromine vapour is stripped using stream and then condensed to liquid. This impure bromine is purified and packed.

The overall efficiency of the process is only 70-75 %

The reaction is as follows:

In the hot process, bittern is acidified to reduce the PH. This is then fed into the main reaction column. Chlorine and Steam are fed from the bottom of the Column. The chlorine replaces the bromine and bromine va pours are passed to the condenser. The condensed bromine with chlorine impurities is passed to the reboiler. In the reboiler the mixture of bromine and chlorine are boiled using steam. As chlorine has a lower boiling point it evaporates leaving behind a rich mixture of bromine

The efficiency of the process is 90-95%

The reaction is as follows: